The first gas detection systems were very primitive. One man on a mining crew would walk down a mine shaft with a lit torch and cover himself with a wet blanket. If he encountered dangerous gas, the flame would ignite it, and the damp blanket would protect him. Of course, the protection frequently failed, and many men were lost.

Gas detection systems eventually improved to where canaries replaced men. The canaries reacted loudly to the presence of gas before it became harmful to humans. Though undoubtedly cruel to the birds, it saved many men’s lives. Fortunately, modern technologies have come a long way since those early days. However, unlike their predecessors, contemporary gas detection systems require regular calibrations. The expert team of technicians at All Protect Systems are registered with the Canadian Fire Alarm Association and are up to date with the latest standards and codes.

Canadian Occupational Safety and Health Administration (OHS)

The Canadian OHS has strict rules governing the use of gas detection systems, and enterprises must conform to these safety regulations. Besides using the appropriate gas detection equipment for your location, you must have them calibrated regularly, not just at the time of installation. Some manufacturers only require semi-annual or quarterly calibration, while others recommend monthly service. The OHS may conduct random visits to your place of business, or they may respond to an employee complaint.

International Electrotechnical Commission (IEC)

The IEC is the international standards organization responsible for all fields of electrotechnology. Their bulletin titled IEC 60079-29-2:2015 gives strict instructions for selecting, installing, using, and maintaining gas detection equipment in both groups one and two. Group one includes equipment measuring flammable gases in underground coal mines, and group two covers electrical devices used in industrial and commercial applications.

Gas Detectors Require Proper Maintenance

Don’t be lulled into complacency by the old adage, “if it ain’t broke, don’t fix it.” Both managers and workers can take the proper functioning of a piece of equipment for granted. Since the squeaky wheel always gets the grease, regular calibration for an otherwise reliable gas detector may get overlooked during routine preventative maintenance schedules. Though natural, this is absolutely the wrong thing to do.

Some workers in plant environments even consider their sense of smell to be superior to the gas detection equipment. Just because someone noticed a gas smell before a detector once upon a time, that doesn’t make it a safe method for something as life-threatening as dangerous gas. Some harmful gases (like carbon monoxide) are odorless, and by the time you smell something, it may be too late.

Why Gas Detectors Need Regular Calibration

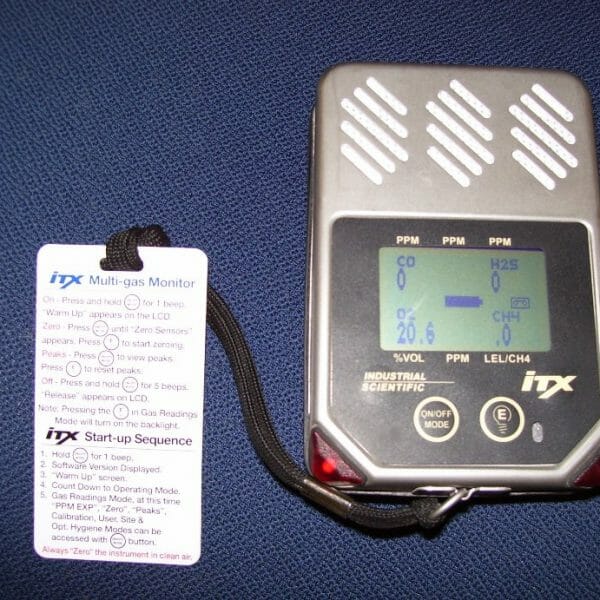

A catalytic sensor’s performance usually degrades and fails from exposure to industrial toxins. Your gas detection equipment is in that environment for a reason, and over time, even safe amounts of these chemicals will ruin your sensors. Calibrate them on schedule or even sooner if they show abnormal signs of wear, or anytime they have been bumped, dropped, or knocked over.

Trained technicians must perform these checks using a precise standard gas mixture. The controller’s zero and span levels must be tuned accurately. While the older and less-expensive systems required two people to perform the calibration, one technician can service modern, high-quality models.

Regardless of whatever type of gas you’re monitoring, or which kind of sensor you’re using, do yourself a favor and have them calibrated regularly. While it may seem redundant and unnecessary, calibrated equipment can reduce your workplace risks and save the lives of your most valuable assets, your employees. Please consider the professionals at All Protect Systems. Located in Waterloo, Ontario, they service the surrounding area. Call them today to schedule your gas detection system calibration!